Available as a standard accessory for all 1x Aliante carbon orders starting from April 2023

all-in-one foot stretcher: unprecedented innovation.

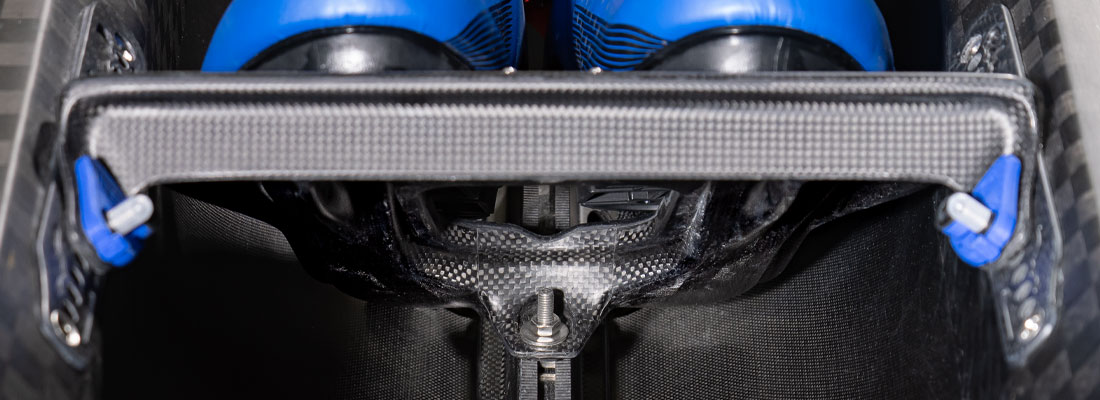

The all-in-one carbon footboard has a brand-new look that also includes the crossbar from the mould. This is a fundamental turning point in rowing shoes, especially in the single, where until today we had not gone beyond the aluminium crossbar passing through various design choices. In reality, in multiple boats, we have witnessed the intermediate passage consisting of carbon crosspieces that were always separated from the main body of the foot stretcher.

With this new profile we have removed the screwed aluminium parts, such as the U-bolts which connected the rear part of the stretcher to the crossbar, in one fell swoop alongside the “wing” plate which was previously fitted with the “millerighe” rack in the keel, which is now integrated into the shape of the stretcher.

In general, we have eliminated all those screwed links among different materials, reducing the dispersion of the thrust produced by the athlete and at the same time the risk of galvanic corrosion among elements.

Our engineers conceived an integrated stretcher profile that offers guarantees in terms of rigidity, to great advantage for the direct transmission of loads to the movement of the boat. Let’s go through this step-by-step, taking into account all of the ingenuity.

Watch the video presentation

Koridion®: a special foam for a solid sandwich.

To create this sandwich, we have made use of one of the latest technologies in the field of foams. The new platform has a core of Koridion®: a preformed undersized foam. Once crystallized and placed inside the carbon stratifications of the mold-platform, the Koridion® is compressed in an autoclave, growing in size and structurally connecting all the areas inside the platform. This improves the compactness of the carbon fiber, making it possible to internally control the stratification while the product is inside the autoclave; a circumstance that cannot be achieved with conventional tools.

The advantages compared with the previous single scull stretcher

200g

lighter

4%

reduction in vibration level

2.7%

increase in thrust

Lighter without screws for a direct push to the boat.

We have embraced this type of innovation and are ready to apply it to future processes. The integrated footrest + crossbar structure without screws guarantees infinitely more direct load transmission with higher rigidity. The same reasoning was applied when we decided to eliminate the screws in the fastening of the racks which are now glued. In this way, it was possible to reduce the thickness of the carbon lamination with an overall dry gain of 200g for each board. The advantages don’t stop there; the environmental sustainability is improved since using this type of non-preformed foam reduces the weight by 20%, consumes 30% less energy and uses 40% less carbon fabric in comparison with the previous process which did not involve a sandwich structure.

Fewer components, better functionality.

In previous shoes, the thickness of the carbon plate created a gap between the toe and heel of the foot that we compensated for with a wedge in the lower part of the shoe. In the new footboard we have raised the bottom to cover for this gap. Now, during the attack cycle, the shoes are parallel to the stretcher without having to mount any adjustment wedge.

The all-in-one stretcher for the single scull.

In the skiff version, the inclination of the external tips of the stretcher (which must go parallel to the gunwale) added to a truss system visible in the lower section make the structure rigid and light and the thrust to the boat becomes immediate.

In fact, if you want to push on the oars, you must transmit pressure through the shoes. With the new stretcher system, there will be risk of structural failures that could happen when there is a transmission of loads from the stretcher to the screw, from the screw to the crossbar, from the crossbar to the boat.

Guaranteed Rotation at 42° and 45°

The wing plate in the lower part of the stretcher warrants a separate discussion. Previously it only worked at 42° and when the shim was applied to obtain 45°, the screw worked at an angle. Therefore, the pressure on the keel could produce a deformation in the boat and therefore deteriorate its fluid dynamics. In the new system there are two holes in the lower part of the platform which allow rotations from 42° to 45°.

To enable such pitches, we added a 3D pre-molded plastic interface to the sides of the stretcher that absorb the vibrations. It is curved and smooth in order to fit perfectly between the drilled reinforcement and the footboard, eliminating gaps and noises that many found frustrating in the past. The interface is inserted when you want to work at 45°. When working at 42° it is not required and is fitted separately at the tip of the stretcher.

We have also redesigned the internal and external reinforcements of the holes on the gunwale: they are now completely carbon. We have therefore eliminated the aluminium, avoiding potential problems around stress-induced corrosion or cracking. Furthermore, the connection between the tips of the stretcher and the drilled reinforcement on the gunwale of the boat is guaranteed by a 316 stainless steel threaded insert with a hexagonal stop to prevent any rotation.

Available as standard accessory for all 1x Aliante carbon orders starting from April 2023 and as an optional accessory for 1x Aliante aluminium.

The new all-in-one stretcher will also be available for doubles, fours and eights in winter 2023/2024

quick-set plate: a new design for the carbon plate.

We have also renewed the design for the fixing plate on the MAS 20 shoe. The objective was to make adjusting the rotation of the shoes easier and faster.

You will no longer need to disassemble the plate from the stretcher: with the new quick-set carbon plate you can find the right angle even whilst sitting wearing your shoes. The classic carbon laminate consists of five components and the weight has not changed compared with the previous model, despite us increasing this by 1mm in thickness. We partially hollowed the plate to insert auxiliary elements that help the adjustment. The quick-set design extends to all plate sizes including the revolving stretcher. All the new models are created to raise the performance of the all-in-one stretcher but can also be fitted with older models.

More info

When will the all-in-one platform be available?

For 1x boats

Starting from April 2023, all new Aliante carbon skiff boats will have the all-in-one stretcher as a standard accessory. On Aliante aluminium skiffs it will be possible to configure it as an optional accessory. On the carbon/aluminium wing rigger single scull, it will not be possible to configure the all-in-one.

For all other boats

We are extending the new technology to all other boat categories: in winter 2023/24 all Aliante carbon boats will have the all-in-one as a standard accessory. For other rigger configurations, the all-in-one will be available as an optional accessory.

Can I set an all-in-one on a 1x bought before April 2023?

No. The old and new stretchers have specific holes in the gunwale. Therefore, the all-in-one cannot be fitted to your boat because it will not have the right drilling.

Will the all-in-one be an optional accessory or already included in the price of the boat?

All Aliante carbon boats will have the new platform as a standard accessory.

On all boats with other boom configurations, the new platform can be configured as an optional accessory. It cannot be configured on carbon/aluminium wing skiffs.

Can I use additional MAS shoes wedges as always?

Yes. The presence of the new plate and the rise of the new platform do not affect the use of the optional wedges to customize the front or rear angle of the foot.

Can I mount a quick-set plate on the old foot stretcher?

Yes. There are no differences in drilling between the old plates and the quick-set.