Created in short carbon fibre. Redesigned teeth. Perfect adhesion and optimised load transmission. Discover all the features of the new rack.

Created in short carbon fibre. Redesigned teeth. Perfect adhesion and optimised load transmission. Discover all the features of the new rack.

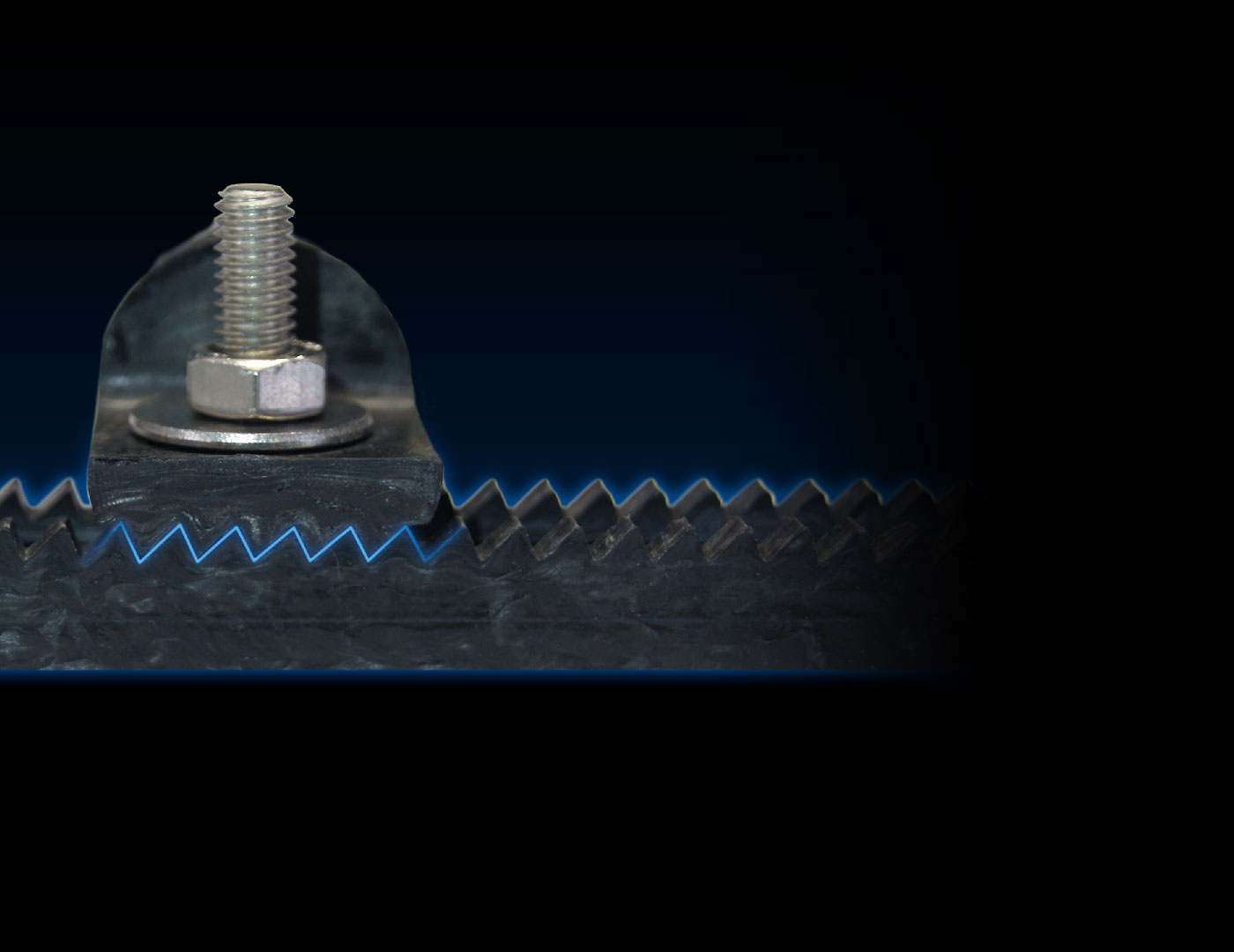

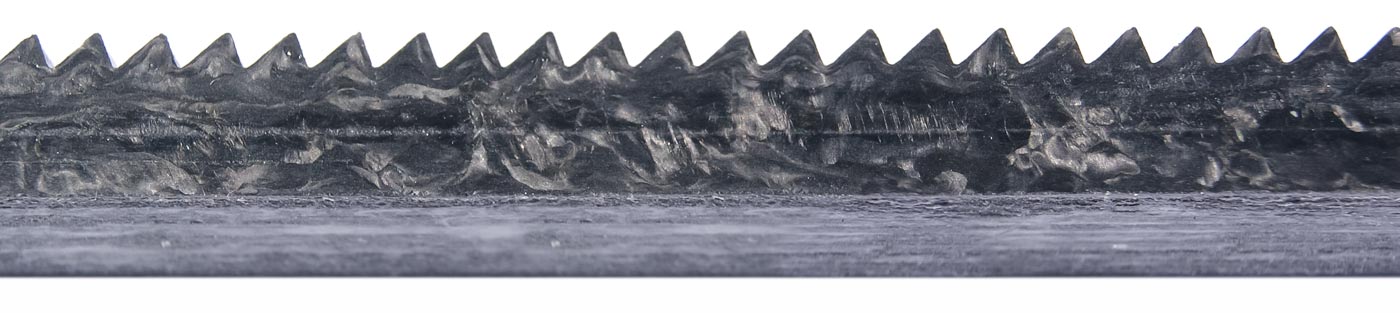

The form of the rack tooth has been modified to ensure that the force from the footstretcher through to the boat passes rigidly between adjacent elements, such as the rack-insert crossbar joint.

The choice fell to a sawtooth joint that has the part of the tooth facing the bow practically in a vertical position, whilst that facing the stern perpendicular to the footstretcher serves to discharge the force of the foot in the proper direction.

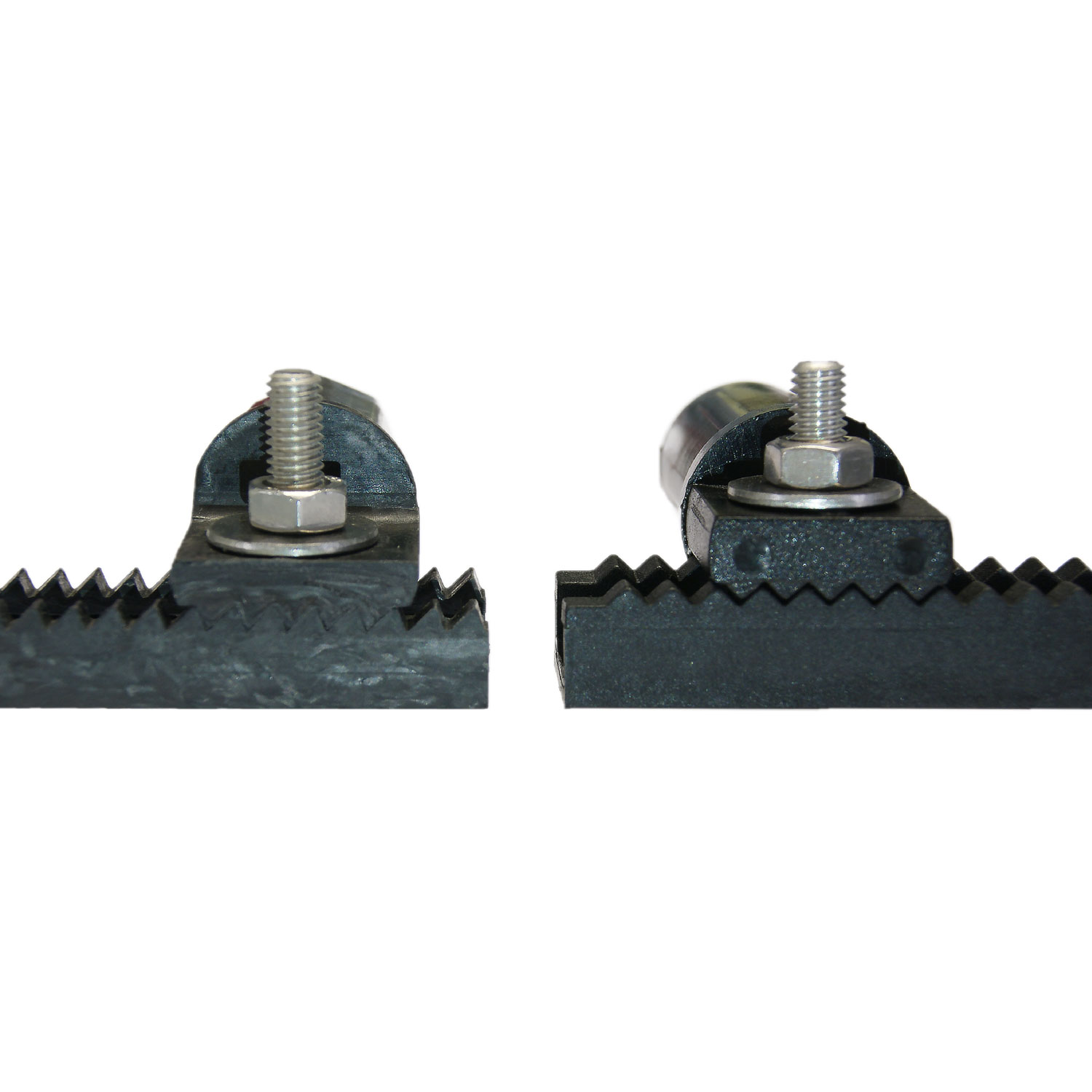

Below: comparison between the new rack in carbon (left) and the standard rack in plastic (right)

In order to optimise the load transmission capacity of the racks and the ribbed shaft, we have chosen to glue them to the boat. Indeed, the entire surface of the components is now perfectly adherent, becoming one with the rowing plane. The force of the rower is entirely channelled into the thrust of the boat.

The crossbar in carbon allows for a significant increase in load transmission. The inserts (ends of the crossbar) also have the saw-tooth system so that they fit perfectly with the rack and are glued to the crossbar rather than embedded, as in the past. The relative sliding between the crossbar and insert is no longer possible, rendering the everything infinitely more rigid. The new clevis, made of the same material as the racks, provides a more rigid attachment between the crossbar and the footboard.

The need for the rack in carbon arose from this series of innovations that prevent deformation, given that the old plastic rack could not support the load without deforming. The footboard is designed to offer full support of the foot, from the heel to the plate (also made of carbon). Thanks to the study of the geometry and the particular layering of materials, we have achieved the maximum rigidity with a decrease in weight, significantly lowering the dispersion of energy (elastic), conveying it in the thrust.

The platform is designed to be placed in the three canonical angles (39°, 42° and 45°) simply by moving the crossbar in the three positions located immediately below the plate of the shoes. In doing so, there is no need to utilise levels, as shims to achieve the desired angle.

The new racks and ribbed shaft, along with the carbon Aliante configuration and MAS shoes, provide the best performance. Watch the video to understand why the Romanian federation has also opted for this configuration.

Our goal is to create a perfectly rigid boat that is able to convey the entire force of the athlete in the right direction, without unnecessary dispersion. Focusing on the footboard area and all its details have resulted in a 9% reduction of elastic energy loss.

This translates into available thrust for the advancement, which allows up to a 4% optimisation of the result.